I did not end up going to the dump today as I did not want to go by myself and no one wanted to come with.

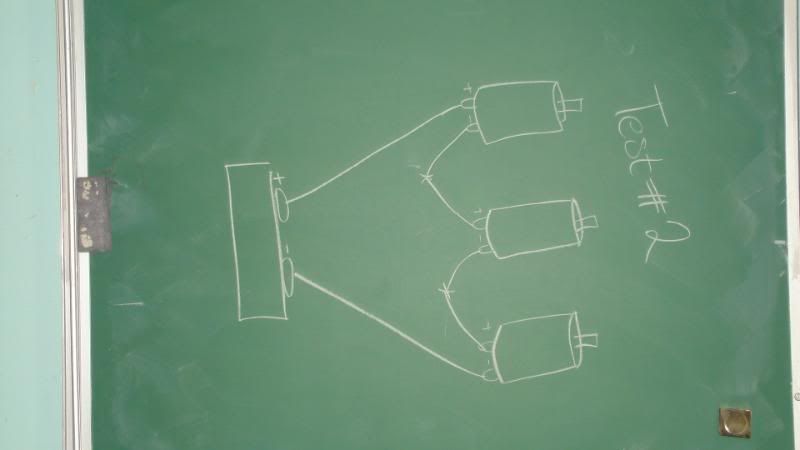

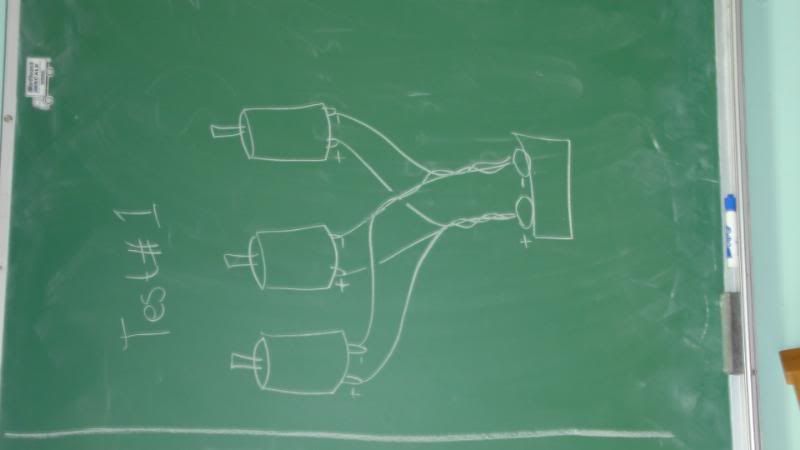

Ethan, Richard, and Max all pointed out a fatal flaw in our design: our pinwheels did NOT line up directly. It was inefficient as, instead of spinning in a smooth circle it spins in actually like this:

Which is not happy.

Sam set about designing a better way to mount the pinwheels while Sarah had an epiphany. Because the blades were so floppy and curling up on themselves, she would iron them between to sheets of cloth. Sheer brilliance I tell you!

We cut those ironed sheets into enlarged versions of our prototype and held it in front of the fan. It still flapped too much. We tried re-enforcing the wings with wire and that made it spin well. Carissa and I began to cut wires off pinwheels, two per our 12 pinwheels, so that we could re-enforce the wings with them while Sam and Sarah ironed the sheets.

Sarah later came back and told us she’d found wooden sticks in the art room, which, of course, are lighter. We had already hot-glued on some of the metal rods but we abandoned that (though we kept the pinwheels we had finished).

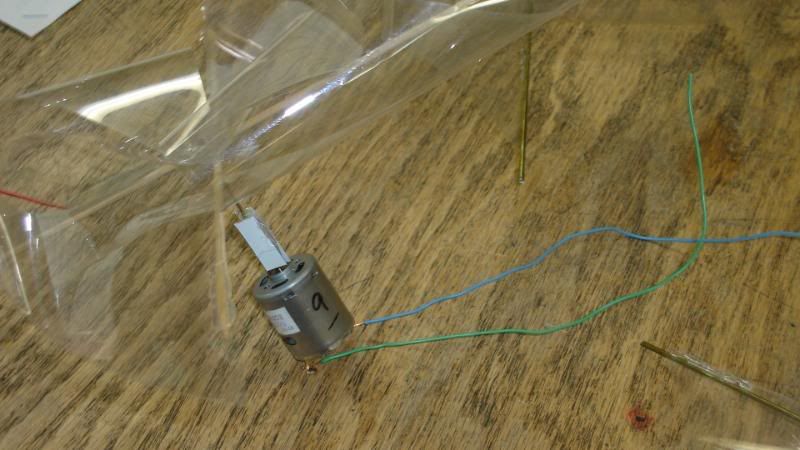

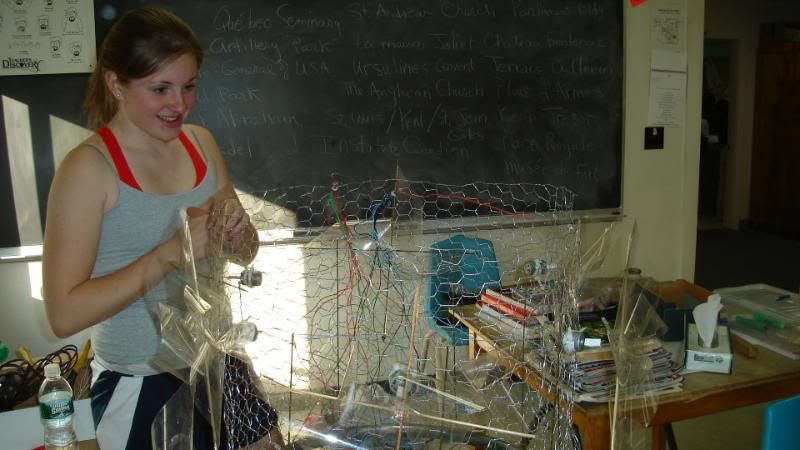

Once Sarah and Sam came down they began to develop a way to hook up our generators onto the pinwheels while Carissa and I glued the ironed sheets to the sticks and T-Pins (a rather tedious process).

S&S, found, after Richard assisted them, that we could cut two rectangles from wax cup and fill them with hot glue, sticking a T-Pin inside while it cooled. Once it had cooled, the T-Pin was removed and the T-Pin attached to a fully-made pinwheel was inserted and secured with Gorilla Glue.

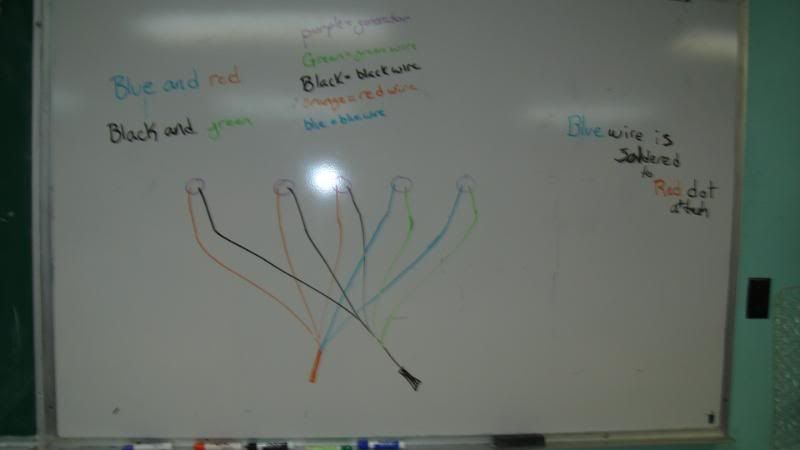

Carissa and I nearly finished and Sam and Sarah stayed after school to finish making the bases for the wheels and begin soldering (spelling?) the wires onto the generators. They will also try and construct a base for our pinwheels to mount themselves on.